Our Blogs

What Is an SS Wool Filter?

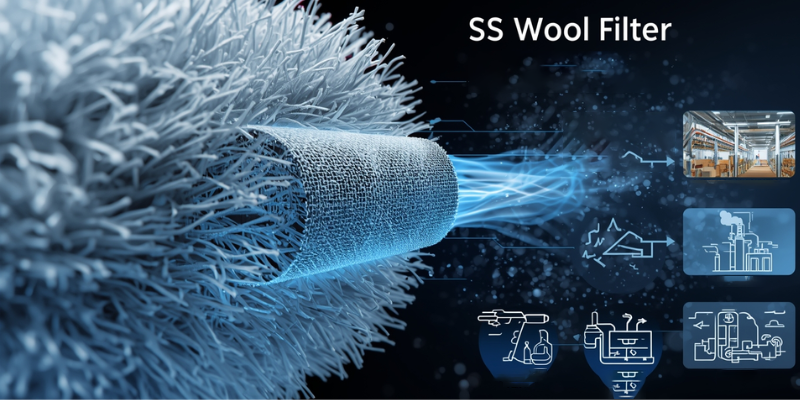

Industries are among the common applications of stainless steel (SS) wool filters in cases where dependable filtration, service life, and tolerance to high temperatures are needed. Although the filtration systems are available in numerous varieties, the SS wool filter is very popular due to its robust structure, long operating life, and the ability to remove impurities effectively. This blog describes the meaning of an SS wool filter, its functioning and its common uses.

Learning about the SS Wool Filter

The SS wool filter consists of thin strands of stainless steel, which are woven together creating a structure resembling wool. These fine metallic fibers form a very fine but porous net-like structure that ensures fluids/gases can travel through but prevents impurities, debris and solid particles. Stainless steel wool does not tear that easily as compared to fabric or paper filters, also compared to fabric or paper filters, the stainless steel wool can endure extreme temperature and pressure.

The filter has a design that gives two forms of filtration:

1. Surface filtration: The large particles are held on the surface.

2. Depth filtration: In which smaller contaminants are trapped between the layers of tightly packed steel strands.

This is the two-action process that renders SS wool filters very effective and reliable when it comes to heavy-duty industrial applications.

How does it work?

The principle of working is easy, but very efficient. When fluid or air flows through the filter, several layers of stainless-steel fibers are exposed to it. The purification of the flow occurs as the flow traverses the closely pressed mesh according to size, density, and resistance to flow. The area of the steel wool that is open to the atmosphere allows a smooth flow and it does not clog easily.

The other benefit is that SS wool filters can be washed and reused several times. They are washable, heatable or can be exposed to cleaning agents without losing their structural integrity, hence making them a cost effective tool of filtration to industries that are used for frequent purposes.

Application of SS Wool Filters

The applications of SS wool filters are diverse in application in different industries. Some common uses include:

• Oil and gas plants: This is used in the filtration of impurities in fuel, lubricants and hydraulic fluids.

• Chemical processing units: These are ideal with aggressive chemicals since stainless steel is unaffected by corrosion.

• Food and beverage production: Aids in the purification of liquids without jeopardizing the level of hygiene.

• Automobile and machinery: Applications include exhaust systems, coolant filtration and high temperature applications.

• Water treatment systems: These are effective in getting rid of fine particles and sediments.

Due to these diverse uses, there is still a demand for an ss wool filter manufacturer in India particularly in industries that require high performance filtration processes.

Advantages of SS Wool Filters

• Great resistance of corrosion caused by stainless steel.

• Reuse design, minimizing cost of running them.

• Operates in high temperature hence industrial capacity.

• Good filtration both against fine and coarse particles.

Conclusion

The SS wool filters are critical in the modern industries since they provide reliable, durable, and efficient filtration to a broad spectrum of applications. They are used by many industries due to their strength, thermal resistance, and reusability as a preferred option to find a stable filtration solution.

Advance International offers a reliable source of filtration products with consistency and engineering to the companies that seek reliable and well-engineered filtration products supported by the experience and attention to quality in the industry.

:

:  :

:  :

:  :

: